Manufacturing Optimization

Manufacturing operations are increasingly complex and the methods and needs to address the challenges are ever evolving with industry trends, technology and business models. Our team knows how to fine tune operations, creating performance across revenue, cost and risk.

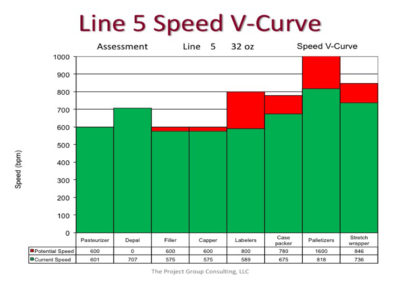

Our team will do a full assessment of your operation to determine where opportunities exist to increase productivity and reduce cost. From the analysis we will propose plans to improve your operation using tools such as root cause analysis, equipment assessments, procedural changes, Kaizen events, and quick changeover workshops.

We have experience leading successful Kaizen events in bottling operations targeting improvement in all aspects of operation including line efficiency, quick changeover implementations, capacity improvements on equipment, maintenance routines and product and packaging yield improvements.

Goals can include developing routines for all aspects of plant production from shop floor to leadership, creating mechanisms to capture corrective measures, installation of downtime information systems, implementing measurements to ensure program adherence and success and plant-wide training to promote a continuous improvement initiative.

When optimization requires major change to the design and operation of your process or system, learn now why the TPGC team is a precision fit with construction solutions.

CONTACT INFORMATION

Mailing: 208 Hewitt Dr., Ste. 103 #342

Waco, TX 76712

254-221-9908

Pamela began her professional career in the broadcast industry while attending Tarleton State University. After graduating with a B.S. in Speech Communication in 1997, she worked at several radio stations in management roles focusing on continuity, music and production as well as serving as an on-air talent continuously for more than ten years. In 2010, Pamela accepted a position as the Assistant Marketing and Development Director for the Eisemann Center in Richardson, TX. Helping to promote, market and develop the City of Richardson’s performing arts center, she succeeded in implementing and managing all social media marketing as well as creating and directing a first-ever student art exhibit, further strengthening her marketing and organizational talents.

Pamela began her professional career in the broadcast industry while attending Tarleton State University. After graduating with a B.S. in Speech Communication in 1997, she worked at several radio stations in management roles focusing on continuity, music and production as well as serving as an on-air talent continuously for more than ten years. In 2010, Pamela accepted a position as the Assistant Marketing and Development Director for the Eisemann Center in Richardson, TX. Helping to promote, market and develop the City of Richardson’s performing arts center, she succeeded in implementing and managing all social media marketing as well as creating and directing a first-ever student art exhibit, further strengthening her marketing and organizational talents. Jason Krueger is the Director of Ranch and Real Estate Development for The Project Group Consulting, LLC. Jason has been managing and developing ranches for greater than 14 years, and has extensive sales management experience in the construction industry dating back to the late 90s. He is also a Wildlife Biologist/Ecologist with a B.S. in Wildlife Ecology from Texas A&M University in College Station.

Jason Krueger is the Director of Ranch and Real Estate Development for The Project Group Consulting, LLC. Jason has been managing and developing ranches for greater than 14 years, and has extensive sales management experience in the construction industry dating back to the late 90s. He is also a Wildlife Biologist/Ecologist with a B.S. in Wildlife Ecology from Texas A&M University in College Station. Bryant began his career at Crepaco warehouse in parts distribution and pump assembly. Then he progressed to field installation for process and ammonia systems where he oversaw welding and fitting both sanitary tubing and ammonia piping systems.He then moved to San Antonio, spent a year as a contract fabricator with H-E-B Foods working for Sanitary Welding Services. At the end of his contract he returned to the DFW area with Alloy Equipment doing installation, crew management, and scheduling. There he remained through the buyout by Statco Fabrication and Engineering, which resulted in his 25 combined years with them moving into engineering and sales departments.

Bryant began his career at Crepaco warehouse in parts distribution and pump assembly. Then he progressed to field installation for process and ammonia systems where he oversaw welding and fitting both sanitary tubing and ammonia piping systems.He then moved to San Antonio, spent a year as a contract fabricator with H-E-B Foods working for Sanitary Welding Services. At the end of his contract he returned to the DFW area with Alloy Equipment doing installation, crew management, and scheduling. There he remained through the buyout by Statco Fabrication and Engineering, which resulted in his 25 combined years with them moving into engineering and sales departments. With more than 25 years in the food and beverage industry and extensive experience as a project manager, Tony has planned and led multi-million dollar projects relating to system upgrades, equipment installation, water quality, validations and process improvements. Some of his areas of expertise include project planning, quality assurance, process analysis, manufacturing systems, process design and problem resolution.

With more than 25 years in the food and beverage industry and extensive experience as a project manager, Tony has planned and led multi-million dollar projects relating to system upgrades, equipment installation, water quality, validations and process improvements. Some of his areas of expertise include project planning, quality assurance, process analysis, manufacturing systems, process design and problem resolution. Tim is an electrical and control systems engineer with more than ten years of experience in a wide variety of industries. Project experience includes working with clients in the water/wastewater fields, pharmaceutical, cosmetics and food and beverage industries. Prior to his engineering work, Tim was a licensed water treatment plant operator in Texas. Tim’s strengths are process engineering, control system design, conveyor system design, and project management. He received his B. S. in Electrical Engineering from the University of Texas at Arlington. In his spare time, Tim enjoys working on cars, golfing, and billiards.

Tim is an electrical and control systems engineer with more than ten years of experience in a wide variety of industries. Project experience includes working with clients in the water/wastewater fields, pharmaceutical, cosmetics and food and beverage industries. Prior to his engineering work, Tim was a licensed water treatment plant operator in Texas. Tim’s strengths are process engineering, control system design, conveyor system design, and project management. He received his B. S. in Electrical Engineering from the University of Texas at Arlington. In his spare time, Tim enjoys working on cars, golfing, and billiards. Michael has thirty-five years of diversified experience in project management and engineering, equipment and systems design, and manufacturing and production. Michael holds a Bachelor of Science degree in Mechanical Engineering from Texas A&M University.

Michael has thirty-five years of diversified experience in project management and engineering, equipment and systems design, and manufacturing and production. Michael holds a Bachelor of Science degree in Mechanical Engineering from Texas A&M University.